Close

For decades, factories needed a human worker to inspect every single product and package for quality assurance. However, machine vision now makes it possible for manufacturers to reduce expenses and increase quality using relatively affordable technology. With machine vision, factories use cameras and artificial intelligence-based technology to capture and analyze images.

2D machine vision became the first widely accepted machine vision technology in factories. With 2D machine vision, factories use imaging to build a holistic, 360-degree view of a part and process, which offers enhanced inspection by detecting the position of product features. The technology applies software algorithms to the production, inspection, and control of mass-produced parts. 2D machine vision rapidly conducts repetitive movements and enables preprogrammed changeover to batch a sequence of production steps, similar to subroutines in computer programming, making it best used for repeated, high-quantity production runs.

Factories see many benefits from 2D machine vision, including:

However, 2D machine learning also has some challenges to overcome. Because machines create the target image using light, 2D machine vision can result in variations from lighting conditions, such as shadows and shading at different times of day, which can make the image less crisp. Additionally, the 2D approach works best for binary assessment, such as determining if a feature of a defect is present, which limits its use cases.

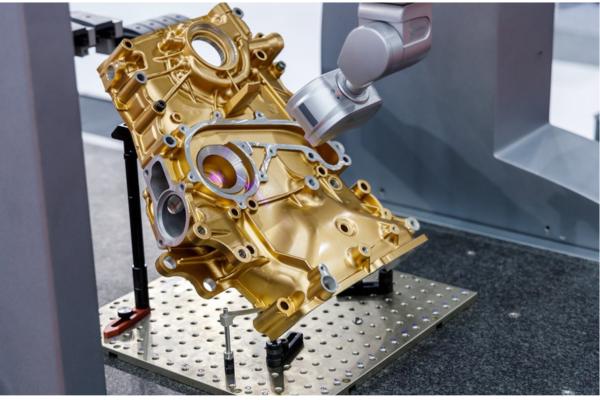

To overcome these challenges, a new and improved imaging solution was released —3D machine vision. However, adding depth to the image requires upgrading the entire process to get closer to the ideal state: zero defects, just-in-time delivery and lowest cost. With 3D machine vision, the sensors and camera capture all three dimensions, which means collecting complete dimensional data for the object.

For example, 3D machine vision can compare a finished part against its computer-aided design (CAD) model to improve quality. Engineers can then develop an inspection sequence to check critical dimensions from the CAD model governed by the engineering drawing or specification. Machine vision then assesses the part against the model in line and either approves the component or rejects it for the scrap bin. By adding the third-dimension data, the inspection process moves from simply a 2D check against the drawing to a direct comparison between CAD and product.

While the process is similar to that of 2D, with the software and algorithms collecting and analyzing data, the third dimension makes it easier to determine the size, shape, location, and position of a defect, significantly increasing the benefits and use cases. The depth dimension also improves the accuracy of the measuring and cutting, which enables a tighter manufacturing tolerance. By achieving a repeatable and tighter tolerance, manufacturers can then automate more of the process, which decreases the per-piece production cost.

Here are two common uses:

Dynamic Response — With 3D machine vision, technology uses imperfection in the image to create an accurate picture by using the feature’s position in the other two dimensions. Because the processes create a more detailed view, technology can respond more quickly to a failure without the need for human intervention. A faster response time moves the process closer to the goal of just-in-time production.

System Performance — Because 3D machine vision enables a faster and more accurate view, engineers can define or preprogram a procedure to assess the severity of part integrity issues. This allows engineers to then optimize the machine to look at known sources of errors, which increases efficiency and decreases part costs.

Moving from 2D-machine vision to 3D requires planning and often some upgrading. Because incorporating the third dimension increases the computational load, machine vision technology providers improved their infrastructure, resiliency, and on-demand computation support to handle the higher demands of 3D machine vision. Although the third dimension increases the costs of processing due to the larger amounts of data, the results provide significant benefits and new use cases better than 2D machine vision can. By taking the necessary steps to transition to 3D-machine vision, manufacturers can gain significant and long-lasting benefits for many years to come.

By clicking ‘Submit’ you agree to our Terms of Use. We take your privacy seriously. For more information please read our Privacy Policy. By registering with Control Automation you will automatically receive our weekly Product Update and Technology Insider eNewsletters.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |